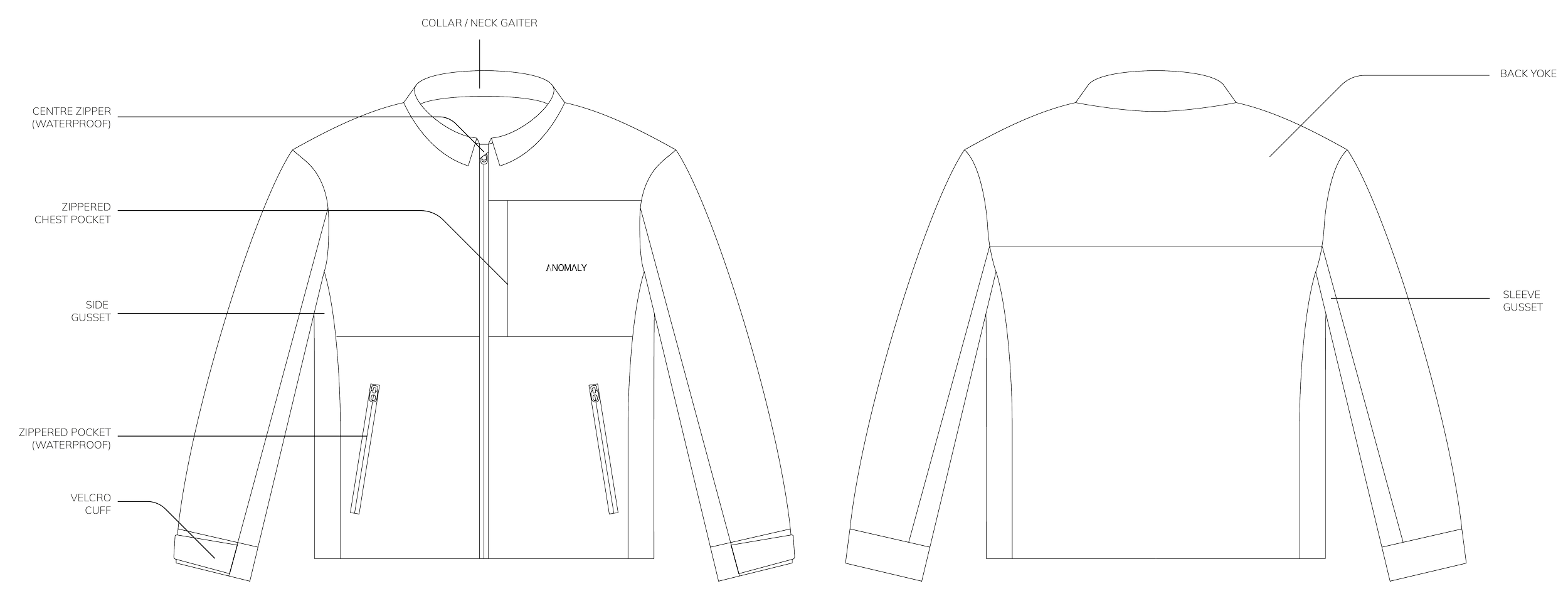

Dutch Coach Jacket

Development of a waterproof, garment-dyed shell jacket.

Technical Developent

Technical Package

Building from the CAD model, I could UV unwrap the geometry into a starting pattern. From here, a tech pack was developed to pinpoint every design detail.

Waterproof Nylon (White)

Synthetic Dye (Green)

YKK Waterproof

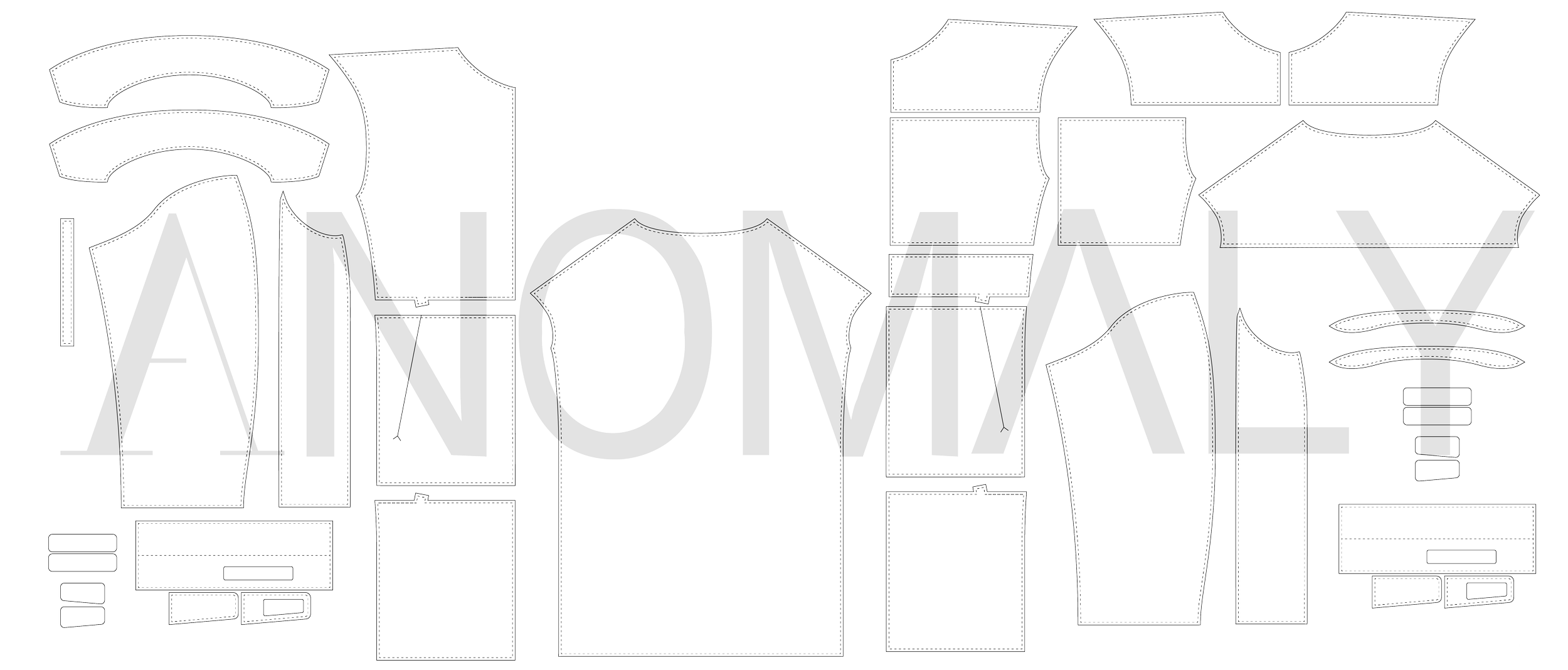

Pattern Making

Exploring new ways for pattern making and cutting, the majority of pattern pieces was laser-cut. Except for a few elements that did not fit. This allowed for an incredible seam tollerance of only 3 mm, reducing bulk in the garment.

Production

Making

This project was a complex merger of multiple cutting, construction, and branding techniques. Using a laser cutter, many panels were carefully cut, and sheets of glue were used to laminate a majority of the jacket. This also included labelling and the internal pocket, which was reinforced with reflective vinyl.

Garment Dyeing

To test and validate the dyeing procedure, I made an accompanying bucket hat. This hat was dyed at 91 C for 30 minutes using a synthetic fabric dye. After washing, the client liked the results, so the jacket was treated in with the same process.

Testing

As part of the Spectrum Program, every element of the jacket was sourced and constructed in white to dye afterwards in a consistent colour. The different materials react differently to the dye. This creates a unique depth and variation in hue.